|

|

Charging Solar

Batteries Inexpensively |

|

|

|

|

|

January 19, 2017 I have a friend that lives off grid

in a beautiful country setting. In the winter when it

rains there is just not enough sun to keep the batteries

fully charged. The charger in his old inverter is rated

30 amps @ 24 volt system. And it is a bit cantankerous

so will cut out if it doesn't feel that the generator is

not providing the proper line voltage. So we started

looking for a solution. First thing that comes up is

finding a used forklift charger. They are around, as I

recall for as little as $.20/watt. But those old

chargers use a line wound iron core transformer. That

makes then pretty heavy and not so efficient. Also, if

it goes belly up, that is it unless you have two of

them; lights out... Then I thought about those

inexpensive power supplies on Ebay used for CNC and

everything else. But these supplies are constant voltage

and won't run up to the 29 volts that is required to

charge a battery bank. It just means they need to be

modified. Great thing is that if you are running a bank

of these things and one goes out, the rest of them just

keep on working. We are running with ten of them. So

150A * 28V is 4200 watts of charging power. Best part, if one supply fails it

does not bring the whole thing down. You just loose 10%

of capacity. And the price point, about 7 cents / watt

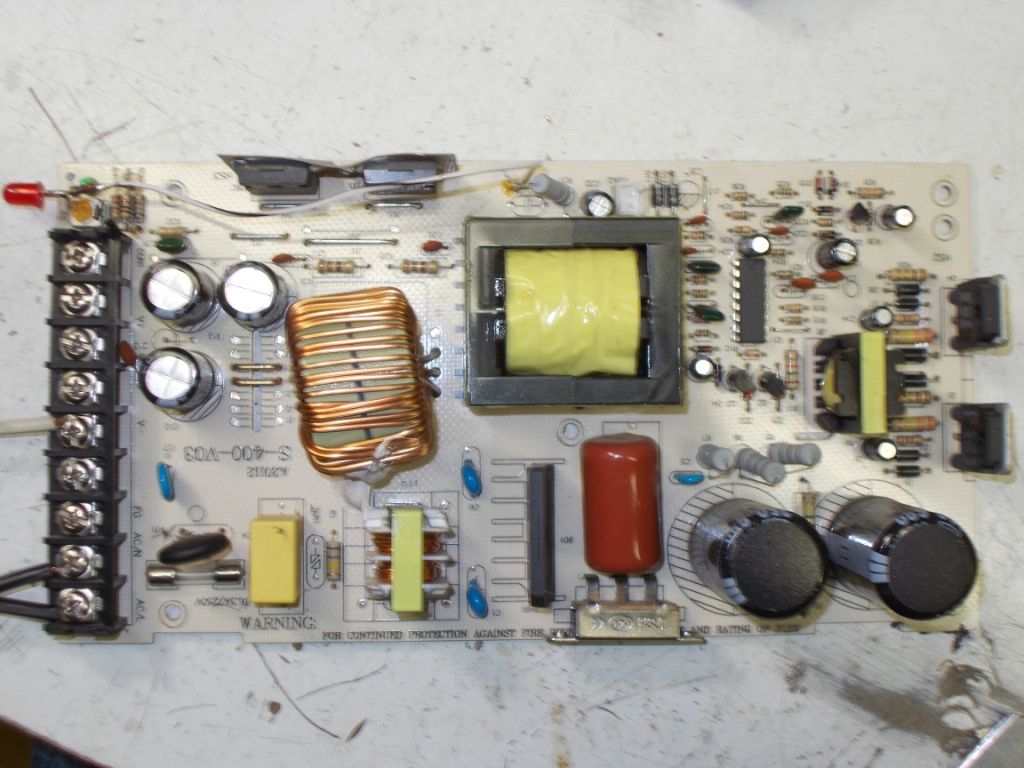

for new equipment! Hard to beat this solution. Here is the board pulled from case: |

|

|

|

|

|

|

|

|

|

|

|

They are built reasonably well built,

especially for the price. This one is rated 15 Amps @ 24

Volts and in the door, ~$25. The weakest point on these

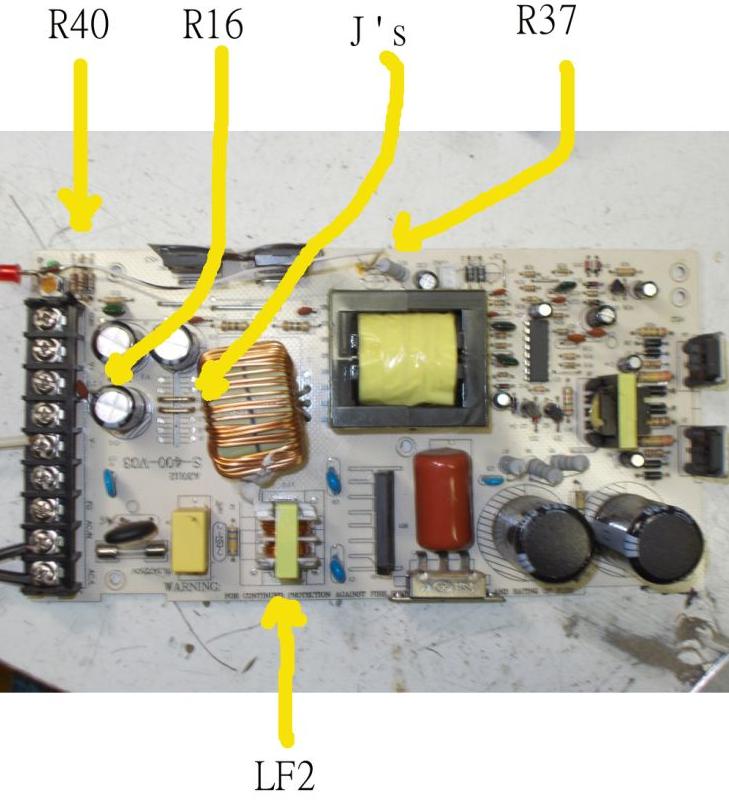

supplies is the input line filter marked LF2 on the

board. I've changed these out as they burn up as we so

far have lost like one a year. I use something like

this, beefy. But in this application it is probably not

even necessary and can be jumped out. |

|

|

|

|

|

|

|

|

Pull R16. It is a bleeder and a phantom load. You don't need to drain the batteries unnecessarily. I added the red LED grounding it to

the voltage adjuster pot and running a wire, via a 220

ohm resistor to R37. This is the running power supply

indicator as the board's green led will always shine

from the batteries. Solder a 10K resistor across R40. This will allow you to set the output voltage above 30V. If you have a puny looking filter

you can just jumper it out. If the supply has a thermostat for

the fan, usually floating inside the large output

inductor, just jumper it out and have the fan run full

time. There is no point in doing any other way in this

application. And most important, trimming the

'J' jumpers. I've seen just one of these supplies that

did not need trimming. Because the supplies will be

running constant current this part of the circuit must

be within specifications. I've damaged a few of these

by not setting this early on as I assumed the current

limiter was good to go. I'd lost the driver

transistors and emitter resistors. So far I've been

able to quickly repair these. So once the

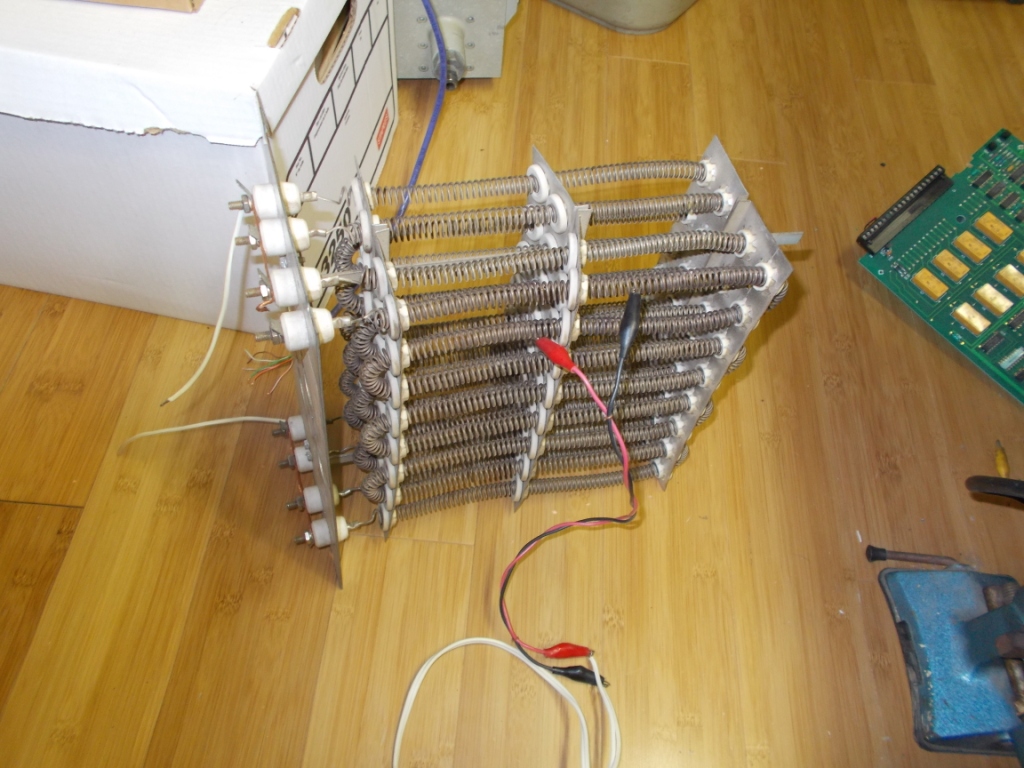

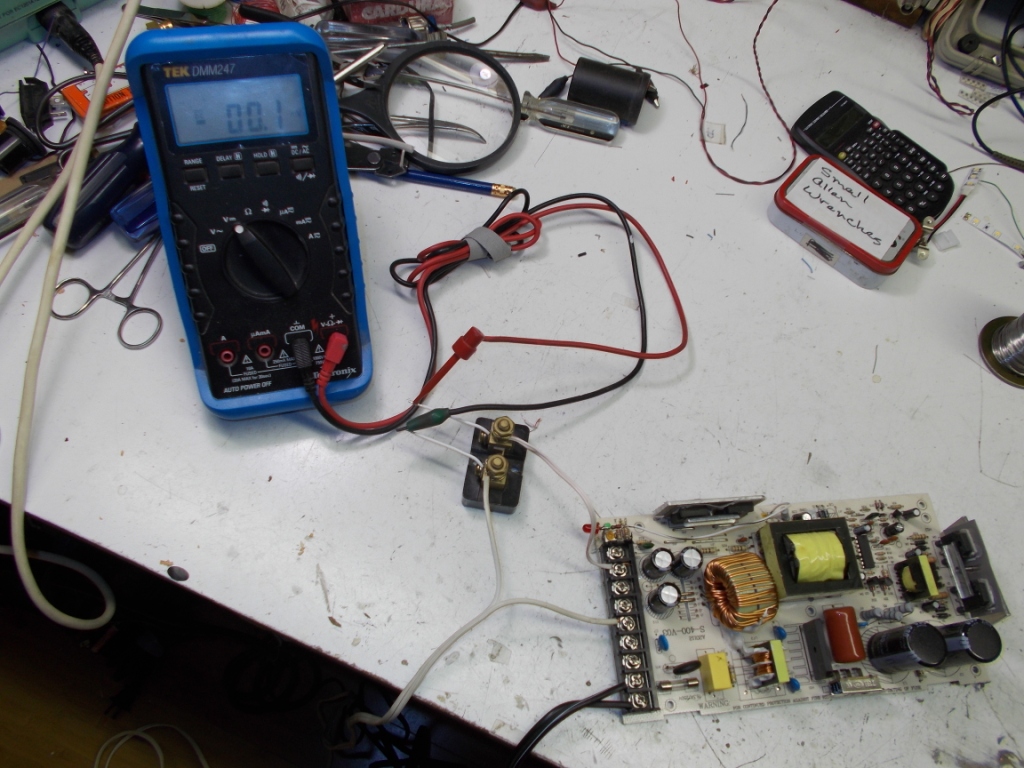

modifications are done, fire it up with a load that

you can adjust. I just used a heater core and set the

jumpers to pull the current I was looking for. Get a couple of small aluminum

plates to put onto your switchers and the output

diode(s). I've seen these come with a one or two diode

configuration. As long as you don't run with a full

load for more than 10 or 15 seconds at a time, they

will work fine.

Yes, this is over 400 watts out. But I've tested at 450 watts out which requires 480 watts in. So the supply will dissipate 30 watts fully loaded. With the fan the output transistors and output diode just get warm at this power. The rating on the output transistors is more than adequate for this service. And the proof is in the pudding, the supplies I've modified are all holding up fine. They are used for 30 to 60 minutes at a time. I'll get a picture of the bank of supplies and put it here:

Thanks, Dan. (pubdan5 at lakeweb dot

net) Copyright

© 1996 - 2017, http://www.lakeweb.net/content/charger.html

|