|

|

The Eagle |

|

|

|

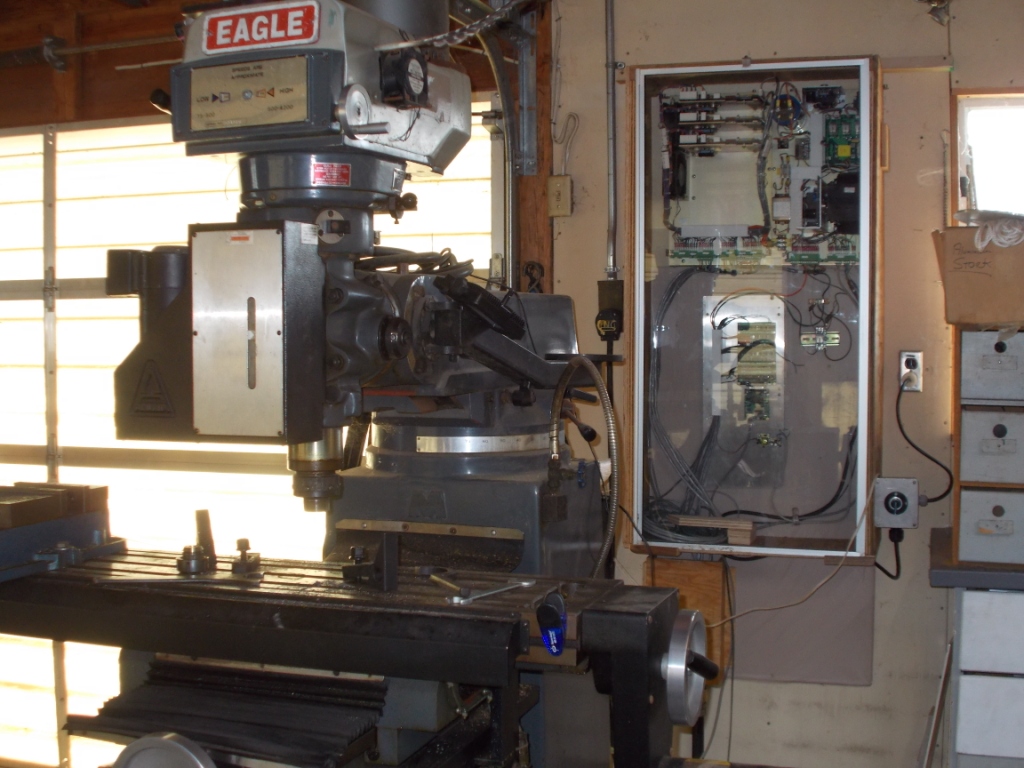

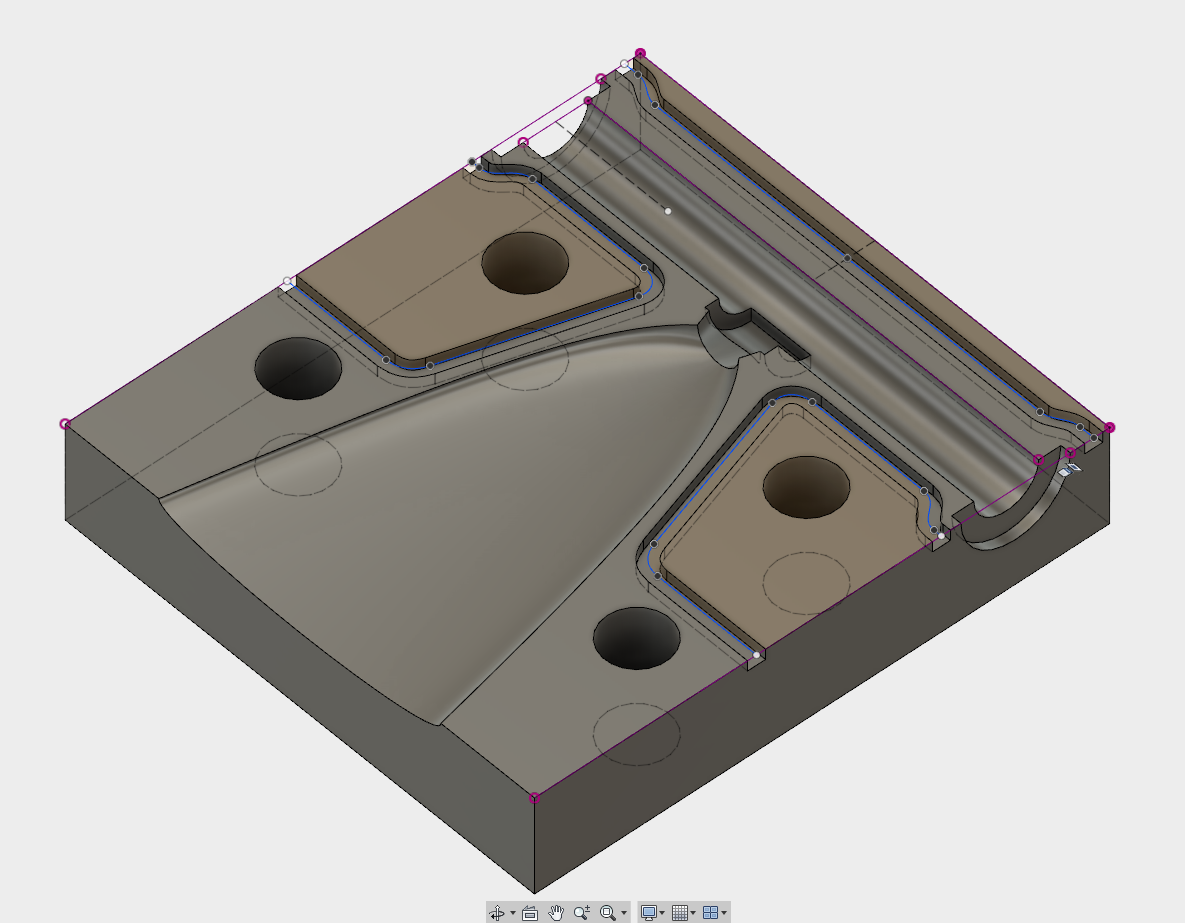

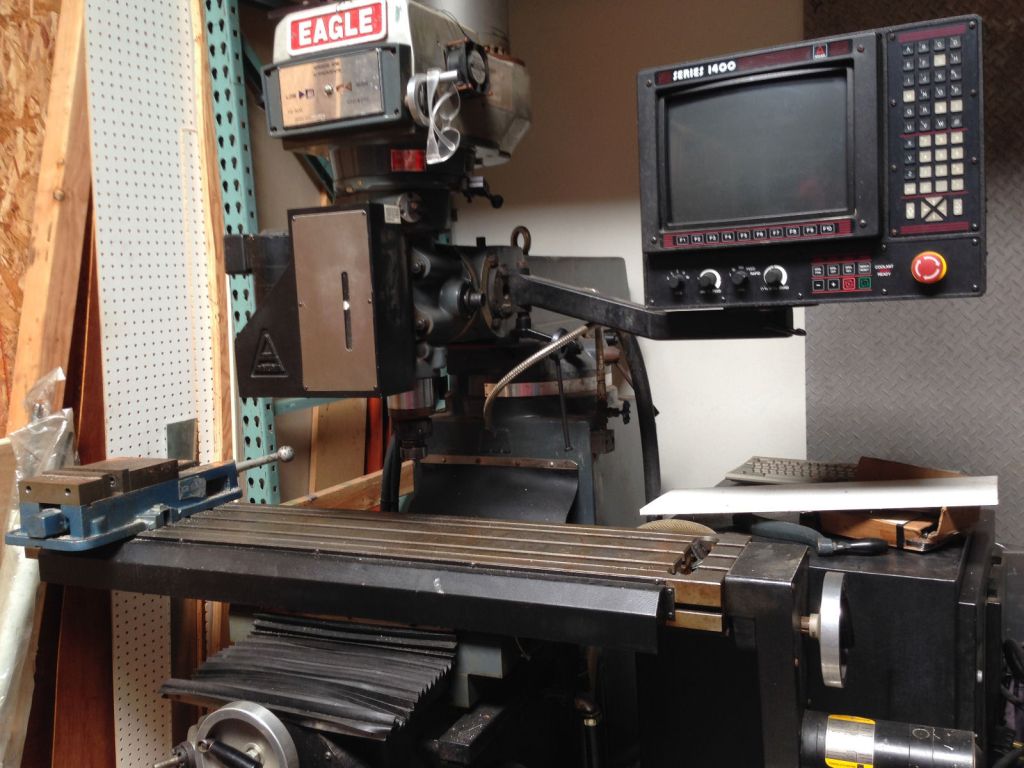

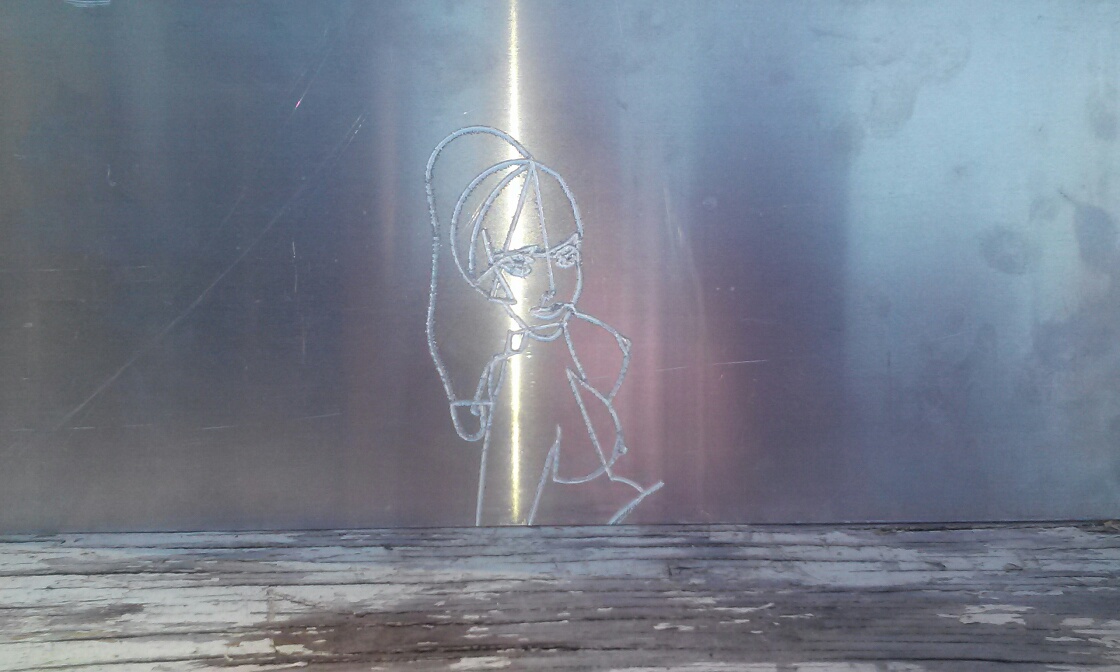

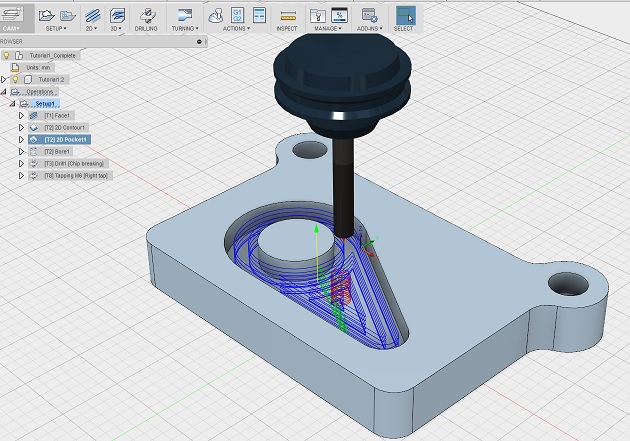

February 13, 2019 Here it is. I finished it a little over a year ago. In the background, the servo drivers from the Anilam box on the top and a Mesa 7i77 and 7i92. Very nice that the connection to the computer is just a LAN cable. That rolls around on a cart in front, so why there is no panel on the mill anymore.  My first paying job!  But I've done more since then. I've cut several stainless part and some aluminum for a guy. More to come as time goes on...  May 29, 2015 This is the EBay photo. That is an Anilam Series 1400 controller.  We have been watching CNC Mills for going on a year. This one was in Santa Clara CA, a day's trip for me to pick it up. It is in very nice condition. I don't think it has ever seen a day of hard work in its life. It has 7000 hours on the meter. I'm figuring it was new in 1992. Yesterday it is still on the back of the truck, but I could not resist, I had to plug it in and see if I could workout the 'fault' advertised in the EBay sale. It had connection diagram for the electronics and I found the UPS was not working properly. This kept the Gateway computer from powering up. There was a switch on the back of the bay to bypass the UPS and it booted. I spent the morning figuring out how to use the Anilam, there is not much documentation out there. I found G-code for a 2D image on the drive and...  What I understand is the first owner was cutting cover plates for 'portable telephones'? Bag phones? I just don't know. First down side, the only way I know of to get new G-code on the box is with a 3.5" floppy. I don't have a running computer with a 3 and a half. There may be a way to RS232 files in but I lack the documentation. I want to get this thing moved to a modern box running LinuxCNC, but that will be down the road. It works with the Anilam so will get used that way for now. First thing is to find documentation on the servo drivers. They are marked 'Servo Dynamics Corp' AW 1410. They are on EBay so I'm guessing pretty wide spread in use today. The motor tachometer comes back into the boards and it looks like just three logic wires per board to control it. I would eventually come up with my own H bridge driver as these could be a real pain to repair without a schematic if one fails. This is up in the air for now. So the adventure starts... (One more pic)  Wow, a year to the day. I played with this some through last summer, but for the most part, it has sat idle. It was time to get back to it so a few days ago I installed Autodesk's Fusion 360. It is all about the CAM. I fired up and found that the Generic Fanuc post processor is very close to the Anilam 1400. If you have used Fusion, you probably recognizes this.  Pretty much right off, I cut this:  I used a 1/2" router bit were the tool in Fusion was 8mm. That is why it doesn't look quite right. For this exercise I was looking to get usable G-code. Mission accomplished. Next is to mull over the Fanuc post processor and modify it so as to make Anilam happy. I bought one of those cheap "USB SSD FLOPPY DRIVE EMULATOR", and put in in the Anilam box. Now I can run out there with a USB flash drive to run code. But I'm still looking forward to the move to LinuxCNC. So far, my research is saying it won't be too painful. Jan 27, 2017 Well, I'd really like to get this done before 2 years go by. I've played with the Amilam enough to really want to upgrade this to linux cnc now. I've done enough research that I'm feeling pretty comfortable about this. I've scoped out the mill to confirm what signals I need. The old box is huge. It even has its own refrigeration system to keep it cool!!! The only thing I'll salvage is the bottom rack, the servo amplifiers. At that, if the servo amps get shaky, I'll upgrade to modern stuff as I can't even find a schematic for the boards. Well, I did find a service manual on ebay a while back for $75. They are loaded with chips and to bench a board and repair it would be more work than it is worth I would think. The servo amps are pretty standard PID drivers taking a feedback for motor tachs. They are driven with a differential +-10 volts so are ready to go with a Mesa servo driver.. The glass outputs a 5 volt digital signal. I was surprised as I've read old glass was typically analog. They step at 5 microns, more than good enough for this mill. Mesa boards are made for this job, but I've been steered into looking at Pico PPMC and the General Mechatronics stuff. The last day I've thought of PC-104 or just PCI in a standard box. My son has a CandCNC system and I really like that it connects to the PC via Ethernet. I'm seriously considering going with a Mesa I/O everything Ethernet board. More to come soon, I'm doing this! |

|

|

Copyright

© 1996 - 2016, http://www.lakeweb.net/CNC/eagle.html

|